Improved a 2O + BAF sludge multiplication integrated sewage treatment equipment (pwt-n Series)

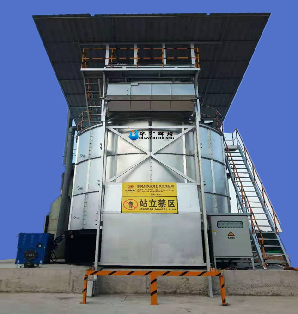

Vertical aerobic fermentation equipment

Integrated sewage treatment equipment for villages and towns (pwt-a Series)

The core technology of PWT, a new water treatment technology combining a / O + MBR membrane process, is to realize the complete separation of HRT and SRT in MBR membrane bioreactor, which can intercept and retain activated sludge and macromolecular organics, save secondary sedimentation tank in traditional process, improve treatment efficiency and ensure effluent quality.

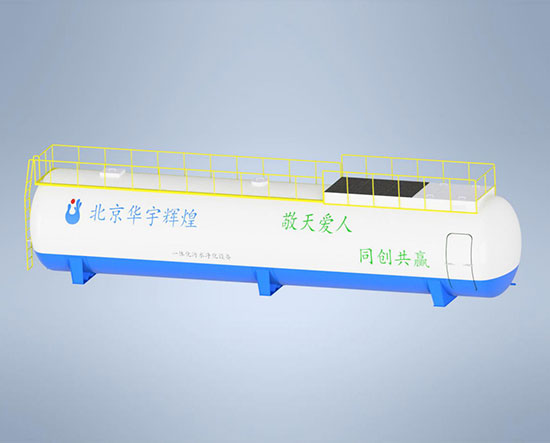

Integrated sewage treatment equipment for villages and towns (pwt-r Series)

Pwt-r series is the upgrade and expansion of pwt-a series, which has the following characteristics: Structure Optimization - one round tank replaces square box, with better structural strength, lower material and manufacturing costs, process optimization - Optimization of process equipment configuration, such as combiner, aeration system, automatic control instrument, etc., to ensure the function is not reduced, and make the process equipment reach the extreme. The energy consumption reduction anoxic tank uses the surplus head kinetic energy of nitrification liquid reflux pump and inlet pump for mixing, reduces the kinetic energy consumption of mechanical mixing and equipment maintenance, and has better water distribution effect.

"Water Magic Cube" wetland ecological purification tank (wet Series)

Good water quality: strong shock resistance, stable effluent. Highly integrated: composite tank design, good hydraulic flow state, no clogging. Easy to operate: less power equipment, simple operation and maintenance free. Good economy: low energy consumption, local treatment and local discharge.

Perishable waste treatment equipment

The composting process is sealed in the fermentation bin, oxygen is provided by forced ventilation, and the materials are fed in and out intermittently in a step-by-step manner. Under the action of high-efficiency bacteria, the organic matter is rapidly degraded, and a large amount of heat is released. The continuous high temperature and water evaporation are maintained. The auxiliary heat system is also equipped to ensure the fermentation temperature and temperature, so as to realize the harmless and reduction of materials.

Low temperature pyrolysis equipment for domestic waste

After simple sorting, the non pyrolytic substances (such as glass and ceramics) in domestic waste are removed Stone, metal, etc.) will be sent to the pyrolysis furnace for pyrolysis. The temperature in the pyrolysis furnace is always controlled at about 250 ℃, so as to realize the efficient and rapid pyrolysis of domestic waste and inhibit the generation of harmful gases.

Kitchen waste treatment equipment

Realize the reduction, harmlessness and resource utilization of kitchen waste in situ treatment

Mobile devices

It is suitable for small and medium-sized emergency domestic sewage and similar industrial organic wastewater treatment

Previous page

1

Next page

Beijing Huayuhuihuang Environmental Protection Technology Co., Ltd.

Phone: 010-61379103

Address: Building 17, Internet Financial Security Demonstration Industrial Park, 1 Yanfu Road, Yancun Town, Fangshan District, Beijing

Business Cooperation: marketing@huayuhuihuang.cn

Copyright © 2020 Beijing Huayuhuihuang Environmental Protection Technology Co., Ltd.

Website building:www.xinnet.com

ICP:16014227号-3

- Follow us -